I looked inside the oil pump to count the amount of washer, just in case I would like to change the oil pressure later.

I have also took dimensions to make a tool if I need too. Always wondered why the drain hole is so big? Well, it's to get the tool through in order to modify the oil pressure.

Used blue loctite on the nut and, this time, I folded the tab correctly ;o)

Actually, the loctite is important; some people do not use the tab washer.

Ready to close it up.

I've painted a dot on the

PMH (

TDC) and the 5 degree mark, and a line on the 30 degree mark.

20 years in storage, the

carbs are very dirty with varnish and the pumps are leaking inside when the engine is running.

New and improved

grose jets (Manufactured by John Titus and designed by

Ansel B.

Grose); The ball turns randomly and never develops a groove. In addition, this can close the fuel intake if the fuel pump delivers higher pressure (In case of after market fuel pumps).

John Titus designed the SM gear reduction starter and coming soon, the

DS gear reduction starter for ALL 5 main bearing engines, including 66-69 with large tooth flywheel.

Installation instructions:

"To ensure gasket remains centered on valve, place gasket on valve and tighten valve finger tight with valve threads facing upward (use grease to hold gasket in place). Invert cover and tighten valve to specifications. Adjust float as

usual."

I have replaced the screw by a stud to facilitate the intake manifold removal and installation.

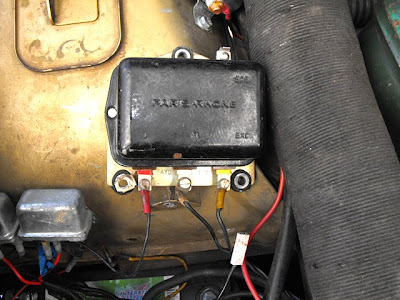

Now it is time to start the engine again. I have hooked up the

oiler and a oil pressure gage (See earliest posts).

The oil showed up at the oil filter, then at the cam shaft. It's time to install the cover, shut off the oiler and start the engine.

Now running and the oil pressure is good...

Ignition and

carbs are not tuned up yet. The engine should sound better soon...